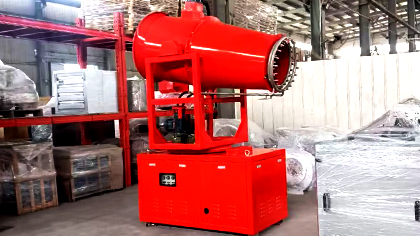

The working environment of dust

suppression sprayers in coal yards

is generally harsh.After ten to fifteen

months of use,the equipment will

be covered by a thick layer of dust.

Therefore,regular maintenance and

inspection of dust suppression sprayers

are crucial to reduce the probability

of equipment failure and extend their

service life.

The maintenance and daily inspection of coal yard dust

sprayers should include the following items:

1.Check V-Belt Tension:Inspect if the V-belt is slack.If there

is slack, adjust it according to the dust sprayer's manual.

2.Lubrication of Plunger Pump:Frequently check if the

lubricating oil and plunger grease in the plunger pump

are sufficient.Add oil if necessary.

3.Inspect Spray Tube and Joints:Examine if the spray tube

is broken or if the spray tube joint gasket is damaged.

Replace if broken or damaged.

4.Lubricate and Clean:Lubricate each lubrication point,

keep them clean,and promptly remove sludge.

5.Electrical Components:Do not disassemble electrical

appliances,avoid colliding with the water nozzle,ensure

the water level is not lower than the height of the pump,

and do not disassemble the equipment yourself.

6.Antifreeze Measures:When the ambient temperature is

below 0°C,take measures to prevent the circulating water

system from freezing and cracking.

7.Prevent Debris Entry:Ensure mud,sand,and debris do

not enter the water tank to avoid blocking pipes and

nozzles or damaging the plunger pump.If the nozzle is

blocked or leaks,shut down the pump to clean and

remove the blockage.

8.Drain Water After Use:After operating the dust sprayer,

drain the water in the machine,especially in low-

temperature areas prone to freezing.Thoroughly drain

the water when not in use to prevent freezing and

cracking of equipment and pipes.

9.Nozzle Condition:Check the condition of the nozzle

for wear or leaks.

10.Inspect Accessories:Verify the normal operation and

condition of the pressure gauge,control valve,and other

accessories.

11.Release Pressure:After use,drain the water in the

pipeline and equipment,and loosen the pressure

regulating handle of the control valve.

Regular maintenance and proper inspection can

significantly enhance the longevity and reliability

of dust suppression sprayers in coal yards.