Pitch Structure Configurations of Fog Cannons:

1.Pull Rod Control:Utilizes a cam transmission mechanism

featuring a speed reducer, cam disc, transmission rod, and

rod sleeve. A decelerating motor rotates the cam disc,

causing the transmission rod assembly to reciprocate

vertically. The rod sleeve on the blower's drive shaft moves

up and down accordingly. Advantages include simple

structure, precise vertical movement adjustment via the

pull rod's fixed position on the cam plate.

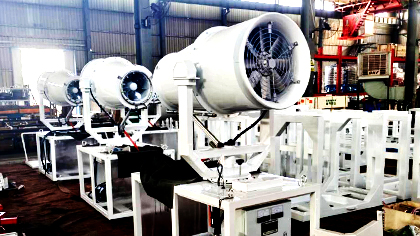

→industrial dust cannon machine

2.Electric Push Rod:A modern electric actuator comprising

motors, push rods, and control devices, enabling remote

and centralized control. Key advantages are its compact

design, high precision, excellent self-locking performance

driven directly by the motor.

3.Hydraulic Cylinder:Powered by a motor, it uses a two-way

gear pump to output pressure oil, controlling the

reciprocating motion of the piston rod via an oil circuit

manifold. Benefits include load start capability, overload

protection, low energy consumption, sealed structure for

longevity, and a self-locking mechanism ensuring the

piston rod remains in position post-motor shutdown.

Applications of Fog Cannons:

1.Industrial Use:Open-pit material storage yards, coal

logistics parks, mining operations, and bulk material

handling sites to control dust during loading, unloading,

and transportation.

2.Construction and Demolition:Dust suppression during

building demolition, construction waste handling, ship

transport, and road dust control from heavy-duty vehicle

operations.

3.Public and Environmental:Airfields, highways, stations,

docks, public spaces, and sports venues for dust

reduction, air cooling, and disinfection.