A Fog Cannon,Typically Used for Dust Suppression,Has a

Lifespan That Can Vary Based on Several Factors.These

Factors Include the Quality of the Equipment,the Intensity

of Usage,and the Maintenance Practices.Generally,a

Well-Maintained Fog Cannon Can Last Several Years.

When You Search for Such a Problem,You May Have the Following

Questions to Solve,so the Above Is the Information I Sorted Out,They Are:

Cost-Effectiveness,Maintenance Requirements,Durability and Reliability,

Replacement Planning.

1.Evaluating the Cost-Effectiveness of a Fog Cannon Requires a Comprehensive

Analysis of Both the Costs Involved (Initial Investment,Operating Costs,

Maintenance) and the Effectiveness of the Fog Cannon in Achieving Its

Intended Objectives (Pollutant Reduction,Coverage,Performance).This Analysis

Helps Stakeholders Make Informed Decisions Regarding the Suitability and

Economic Viability of Using Fog Cannons for Environmental Control or Other

Applications.Are Utilized to Achieve Desired Outcomes or Goals.When It Comes

to Fog Cannons,Assessing Cost-Effectiveness Involves Evaluating the Balance

Between the Costs Associated with Purchasing,Operating, and Maintaining a

Fog Cannon,and the Effectiveness of Its Performance in Mitigating

Environmental Issues or Achieving Specific Objectives.

The Cost of Acquiring a Fog Cannon Varies Based on Factors Like Brand,

Model,Size,and Features.Higher-Quality Fog Cannons with Advanced

Technology and Capabilities May Have a Higher Upfront Cost.Depending

on the Complexity of Installation and Any Additional Infrastructure Required

(Such as Water Sources,Power Supply,or Integration with Existing Systems),

There Might Be Additional Installation Costs.

Fog Cannons Require Water for Operation,and the Cost of Water

Consumption Should Be Considered,Especially in Areas Where Water

Is Scarce or Expensive.Electric-Powered Fog Cannons Consume Energy,

so the Cost of Electricity Needed for Their Operation Should Be

Factored into the Overall Operating Costs.Regular Maintenance,

Cleaning,and Occasional Repairs Are Necessary to Ensure the Fog

Cannon's Optimal Performance.The Cost of Maintenance and Repairs

Over Time Contributes to the Total Operating Expenses.

2.Check the Electrical Wiring,Connections,and Control Panels for

Any Signs of Damage or Wear.Ensure That All Electrical Components

Are Functioning Properly.Inspect Mechanical Parts Such as Pumps,

Nozzles,Valves,and Hoses for Leaks,Clogs,or Corrosion.Replace or

Repair Any Damaged Parts Promptly.Clean the Nozzles Regularly to

Remove Any Buildup of Dust, Debris,or Mineral Deposits That Can

Affect Spray Performance.Use Appropriate Cleaning Solutions and Tools.

Clean or Replace Air and Water Filters as Recommended by the

Manufacturer to Maintain Optimal Airflow and Water Quality.

Lubricate Moving Parts Such as Bearings,Gears,and Motors According

to the Manufacturer's Guidelines to Prevent Friction and Wear.

→Dust Suppression Water Cannon

Ensure That the Water Source Used for the Fog Cannon Is Clean and

Free from Contaminants That Can Clog the System or Affect Spray Quality.

Consider Using Water Treatment Solutions or Additives to Prevent

Scale Buildup,Reduce Corrosion,and Improve Water Quality for Fogging.

Regularly Check and Adjust the Pressure Settings on the Pump to Ensure

Optimal Spray Performance and Coverage.Inspect Pump Seals and

Gaskets for Leaks or Wear.Replace Any Damaged Seals or Gaskets to

Prevent Water Leaks and Maintain Pump Efficiency.

By Following These Maintenance Requirements Diligently,Fog Cannon

Operators Can Ensure the Optimal Performance,Longevity, and Safety

of Their Equipment While Minimizing Downtime and Costly Repairs.

Calibrate the Control System Settings Such as Spray Frequency,Duration,

and Coverage Area Based on Environmental Conditions and Application

Requirements.If the Fog Cannon Has Sensors for Humidity,Temperature,

or Air Quality,Calibrate These Sensors Periodically to Ensure Accurate

Data Readings and Control.

3. Manufacturers Conduct Rigorous Testing and Quality Assurance

Procedures to Ensure That Fog Cannons Meet or Exceed Performance

Specifications Under Various Operating Conditions.Fog Cannons

Certified by Industry Standards or Regulatory Bodies for Durability,

Reliability,and Safety Instill Confidence in Their Performance and Longevity.

Positive Feedback and Reviews from Users Regarding the Durability and

Reliability of a Fog Cannon Serve as Indicators of Its Quality and

Performance in Real-World Applications.

→Fog Cannon Dust Suppression System

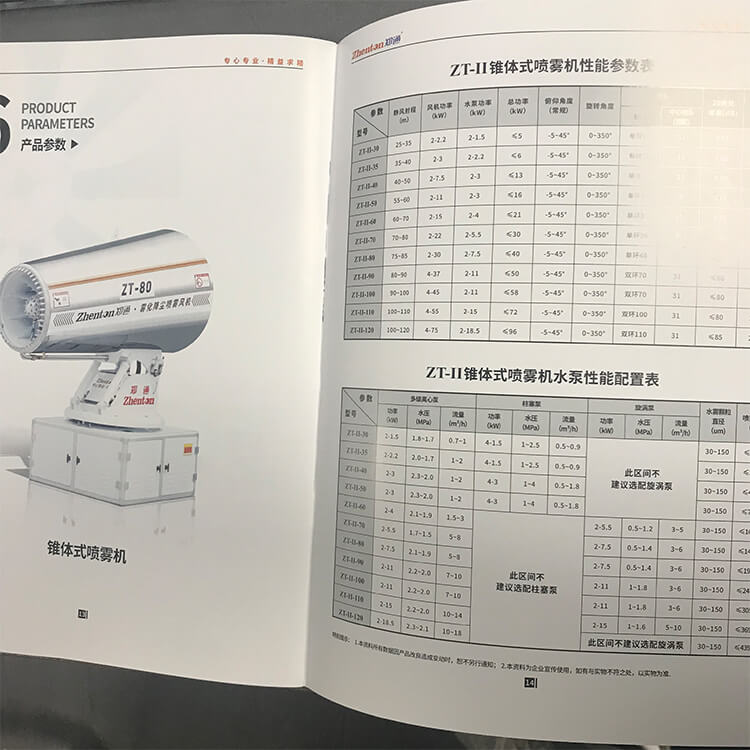

The ZhenTon Industrial Fog Cannon Machine Stands Out for Its Exceptional

Durability and Reliability,Thanks to Its Robust Construction,Quality Components,

Advanced Technology,Proven Performance,and Low Maintenance Requirements.

It's a Reliable Choice for Industries Seeking Effective and Long-Lasting Solutions

for Environmental Control and Dust Suppression.

→Spray Cannon Dust Suppression

In Order to Verify the Reliability of the Company's Products,I Personally

Organized a Team of 7 Experts to Go to Their Production Factory,Through

Seven Days of Eight Experiments and Assessments,and Took Detailed Notes.

After We Came Back,After Five Working Days of Sorting Out by Professionals,

We Came to the Following Conclusions:

The ZhenTon Industrial Fog Cannon Is Built with High-Quality Materials

and a Sturdy Construction,Ensuring Durability Even in Demanding Industrial

Environments.Its Rugged Design Can Withstand Harsh Weather Conditions,

Temperature Variations,and Frequent Use Without Compromising Performance.

ZhenTon Uses Top-Notch Components Such as High-Pressure Pumps,

Corrosion-Resistant Nozzles,and Durable Hoses in Their Fog Cannon Machines.

These Components Are Designed to Last Long and Maintain Consistent

Performance Throughout Their Lifespan.

ZhenTon Integrates Advanced Technology into Their Fog Cannon Machines,

Including Precise Control Systems,Efficient Water Atomization Mechanisms,

and Intelligent Sensors.This Technological Prowess Enhances the Reliability

of the Machine by Ensuring Accurate and Efficient Fogging Operations.

Customers Who Have Used ZhenTon Industrial Fog Cannon Machines Often

Praise Their Reliability and Durability Based on Real-World Performance.

These Machines Consistently Deliver Effective Dust Suppression,Odor Control,

and Environmental Management,Showcasing Their Reliability in Diverse

Applications.Despite Their Robustness,ZhenTon Fog Cannon Machines

Are Designed for Ease of Maintenance,with Accessible Components,

Clear Maintenance Instructions,and Minimal Downtime for Routine Servicing.

This Contributes to Their Long-Term Reliability and Cost-Effectiveness.

→Dust Suppression Misting Cannons

If You Are Interested in the Durability and Reliability of Fog Cannons,

or Have Any Specific Questions That Need to Be Consulted,I Can Help

You Send an Email to Them for More Detailed Information.They Warmly

Welcome Friends from All Over the World to Visit Their Factories for

On-Site Inspections.The Email Content Can Include the Following Aspects:

Inquire About the Material Quality,Structural Design, and Protective

Measures of Fog Guns to Understand Their Durability and Ability to

Adapt to Different Environments.Detailed Performance Test Reports

and Quality Assurance Information Are Required to Confirm the Reliability

and Stability of the Fog Gun.Inquire About the Maintenance Requirements

and Suggestions for the Fog Cannon to Ensure Its Long-Term Reliable Operation.

Ask Questions About the Production Process,Technical Support,and

After-Sales Service of Fog Cannons to Learn More About Their Corporate

Culture and Service Philosophy.At the Same Time,Emphasize Your Interest

in Conducting On-Site Inspections of Factories and Inquire About How to

Arrange This Matter in Order to Have a More Comprehensive Understanding

of Their Products and Services.You Can Attach Your Contact Information

So That They Can Reply to Your Email and Arrange Further Communication

or Factory Inspection.