In the mining industry, effective dust suppression is not only crucial for maintaining a healthy working environment but also for ensuring compliance with environmental regulations. Dust particles in mines can cause serious respiratory problems for miners and have a detrimental impact on the surrounding ecosystem. However, when winter arrives, the task of dust suppression becomes significantly more arduous.

1. Advanced Anti - Freeze Design

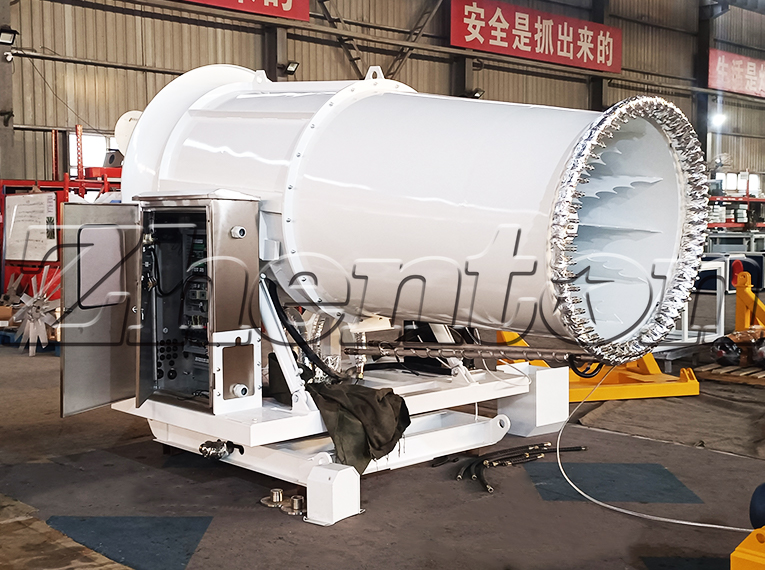

Anti - freeze and insulated mist cannon machines are crafted with state - of - the - art anti - freeze technology. They are equipped with specialized heating elements or employ anti - freeze fluids within their water systems. These heating elements are capable of maintaining the water temperature above the freezing point, ensuring that water flows smoothly through the hoses and nozzles. For instance, in extremely cold mine environments where temperatures can plummet well below zero, the anti - freeze system activates promptly to prevent ice formation, enabling the mist cannon machine to continue its dust - suppression tasks without interruption.

2. Superior Insulation for Equipment Protection

These machines are outfitted with high - quality insulation materials. The insulation not only aids in retaining the heat generated by the anti - freeze system but also safeguards the equipment's internal components from the harsh cold. The insulation layer functions as a barrier, reducing heat loss and preventing the cold from affecting the electrical and mechanical parts. This ensures that the mist cannon machine can operate stably in frigid conditions, minimizing the risk of breakdowns due to low temperatures.

3. Efficient Dust - Suppression Performance

Despite the cold weather, anti - freeze and insulated mist cannon machines do not compromise on their dust - suppression capabilities. They still utilize advanced atomization technology to generate a fine mist that can effectively capture dust particles in the air. The wide - range spraying feature remains intact, covering large areas of the mine site. Whether it's a large - scale open - pit mine or an underground mine with intricate layouts, these machines can reach every corner to suppress dust, just like their non - winter - specific counterparts.

4. Adaptability to Different Mine Conditions

These specialized mist cannon machines exhibit high adaptability to various mine conditions. They can be adjusted in terms of spraying angle, height, and the volume of the mist according to the specific requirements of the mine. In mines with diverse terrains and dust - generation sources, the anti - freeze and insulated mist cannon machines can be easily configured to target the areas with the highest dust emissions. This adaptability makes them an ideal choice for different types of mines, regardless of their size or geographical location.

Conclusion: Transforming Winter Mine Dust Management

In conclusion, the anti - freeze and insulated mist cannon machine has emerged as a revolutionary solution for winter mine dust suppression. Its innovative anti - freeze design, superior insulation, efficient dust - suppression performance, and adaptability to different mine conditions make it the preferred choice for mines operating in cold climates. By employing these machines, mines can ensure the health and safety of their workers, protect the environment, and maintain seamless operations even during the harshest winter months. It is truly revolutionizing the way we manage dust in mines during winter, paving the way for a more sustainable and productive mining industry.