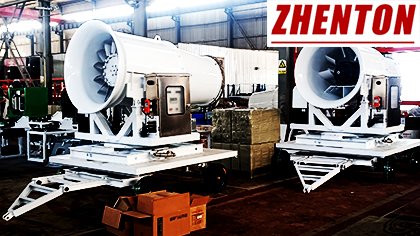

A Fog Cannon Dust Suppression System is Designed to Tackle The Problem of Airborne Dust Particles Generated By Activities Such as Open Mining,Demolition,and Bulk Material Handling.These Systems are Highly Effective,With The Ability to Suppress Up to 95% of Airborne Dust Particles.

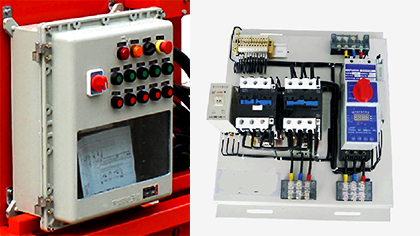

An Explosion-Proof Electric Control Box is Essential For Ensuring The Safe Operation of The Fog Cannon System in Hazardous Environments Where There May Be a Risk of Explosions.These Control Boxes are Designed to Withstand Harsh Conditions and Prevent The Ignition of Surrounding Flammable Gases or Particles.

Integrating a Fog Cannon Dust Suppression System With an Explosion-Proof Electric Control Box is a Comprehensive Solution For Managing Dust in Hazardous Environments.This Combination Ensures Effective Dust Suppression and Enhances Operational Safety,Making It a Valuable Investment For Industries Dealing With High Dust Levels and Potential Explosion Risks.

Explosion Protection:The Primary Function of an Explosion-Proof Electric Control Box is to Prevent Sparks or Electrical Components From Igniting Flammable Gases or Dust Particles Present in The Atmosphere.This is Achieved Through Robust Construction and Sealing That Can Withstand Potential Internal Explosions Without Propagating Them to The External Environment.

High Durability:Designed to Withstand Harsh Environmental Conditions,These Control Boxes are Typically Made From Rugged Materials Such as Stainless Steel or Aluminum Alloy,Ensuring Longevity and Reliability.

Integrated Safety Features:They Incorporate Specialized Safety Features Such as Overcurrent Protection,Short-Circuit Protection,and Thermal Overload Protection.These Features Prevent Electrical Malfunctions That Could Lead to Hazardous Situations.

Remote Control Compatibility:Many Modern Electric Control Boxes are Equipped With Remote Control Capabilities,Allowing Operators to Manage The Fog Cannon System From a Safe Distance.This Feature Enhances Operational Efficiency and Safety.

Ease of Installation and Maintenance:They are Designed For Easy Installation and Maintenance,Often Featuring Modular Components That Can Be Replaced or Upgraded Without Extensive Downtime.

Compliance With Standards:Explosion-Proof Electric Control Boxes Comply With International Safety Standards Such as ATEX (Atmosphères Explosibles),Ensuring Their Suitability For Use in Potentially Explosive Atmospheres.

Fog Cannon Dust Suppression Systems With Explosion-Proof Electric Control Boxes are Essential Tools in Industrial Settings Where Dust Control and Safety are Paramount.Their Effectiveness,Combined With Advanced Features Such as Remote Control and Portability,Make Them a Valuable Investment For Improving Workplace Safety and Environmental Standards.

Modern Fog Cannon Systems Often Come Equipped With Remote Control Capabilities,Allowing Operators to Control The System From a Safe Distance.This Feature Enhances Safety and Convenience,Especially in Hazardous Environments.

These Systems are Versatile and Can Be Used in Various Industrial Applications,Including Demolition Sites,Construction Projects,and Mining Operations.Portable Models are Also Available,Making it Easier to Move The System to Different Locations as Needed.

An Explosion-Proof Electric Control Box is a Crucial Component in Fog Cannon Dust Suppression Systems,Especially in Hazardous Environments Where There's a Risk of Explosive Gases or Dust.Here Are Some Key Features and Benefits:

Enclosure Material:Typically Made From Stainless Steel (Such as 304 or 316 Grade) or Aluminum Alloy For Corrosion Resistance and Structural Strength.

Sealing Materials:High-Performance Sealing Materials Like Silicone or Fluororubber Ensure Effective Environmental Sealing Inside and Outside The Control Box.

→Fog Cannon Dust Suppression System

Manufacturing Process:Precision Machining and Welding Processes Ensure Robust Enclosure Structure and Sealing Performance.

Installation of Internal Electrical Components Adheres to Stringent Technical Requirements to Prevent Electrical Sparks and Effectively Isolate Circuits to Prevent Fire or Explosion Hazards in Hazardous Environments.

Explosion-Proof Design Features: Internal Component Design Prevents Electrical Sparks and Effectively Isolates Circuits to Prevent Fire or Explosion Hazards in Hazardous Environments.

→Dust Suppression Water Cannon

Installation Location and Environmental Adaptability:Select Suitable Installation Positions and Methods Based on Specific Environmental Requirements to Ensure Effective Operation and Ease of Maintenance.

Consider Ambient Conditions Such as Temperature,Humidity,and Chemical Exposure,Choosing Appropriate Protective Measures and Accessories.

Maintenance and Service:Provide Accessible Control Panels and Connection Ports For Regular Maintenance and Inspections.

Regularly Inspect Seals and Grounding Devices to Ensure Long-Term Reliability and Safety of The Explosion-Proof Electric Control Box.

At ZhenTon,We've Honed our Craft Over Two Decades,Specializing in Top-Notch Fog Cannon Machines and Explosion-Proof Electric Control Boxes.Our Fog Cannons are Designed to Tackle Dust and Particles With Precision,Making Workplaces Cleaner and Safer Effortlessly.

What Sets Us Apart?Our Explosion-Proof Electric Control Boxes are Meticulously Crafted and Certified to Global Standards Like IECEx and ATEX. Built Tough With Stainless Steel or Aluminum Alloys,They Ensure Reliability in Even The Harshest Environments,Minimizing Fire and Explosion Risks With Advanced Safety Features.

When You Choose ZhenTon,You're Choosing Reliability,Innovation,and Peace of Mind.Experience The Difference With Our High-Performance Fog Cannons and Safety-Focused Control Boxes,Tailored to Meet Your Toughest Challenges.Learn more