When it Comes to Dust Suppression Misting Cannons,Utilizing Explosion-Proof Motors is Crucial For Safety in Hazardous Environments.These Motors Are Designed to Prevent Ignition of Flammable Gases or Vapors Present in The Atmosphere,Reducing The Risk of Explosions.They're Often Used in Industries Like Mining,Chemical Processing,and Oil Refineries Where Combustible Dust or Gases Are Common.

Explosion-Proof Motors Play a Crucial Role in Enhancing The Safety and Functionality of Dust Suppression Misting Cannons,Particularly in Hazardous Environments Where Flammable Gases or Dust Particles May Be Present.

Here are The Key Insights:

Safety in Hazardous Environments:Explosion-Proof Motors are Designed to Prevent Ignition of Surrounding Gases or Dust Particles.They Achieve This Through Robust Construction and Sealing Techniques That Contain any Sparks or Heat Generated Within The Motor Itself.This Capability Significantly Reduces The Risk of Fire or Explosion,Making Misting Cannons Safer to Operate in Industries Such as Mining,Construction,and Oil Refining.

Functionality and Reliability:By Using Explosion-Proof Motors,Misting Cannons Can Maintain Operational Integrity Even in Challenging Environments With High Levels of Airborne Particulates.These Motors are Built to Withstand Corrosive Substances and Harsh Conditions Without Compromising Performance.Here are Some Key Features and Benefits of Explosion-Proof Motors:

Robust Enclosures:Explosion-Proof Motors Have Heavy-Duty Enclosures That Can Withstand Internal Explosions.These Enclosures Prevent The Spread of Flames or Sparks to The Outside Environment.

Sealed Components:all Electrical Components are Tightly Sealed to Prevent The Ingress of Hazardous Materials,Ensuring Safe Operation Even in Volatile Conditions.

Specialized Materials:These Motors are Constructed Using Materials That are Resistant to Corrosion,High Temperatures,and Impact,Enhancing Their Durability and Reliability in Harsh Environments.

Temperature Control:Explosion-Proof Motors Often Include Temperature Control Mechanisms to Prevent Overheating,Which Could Lead to Potential Ignition Sources.

Certification:These Motors are Certified By Various Safety Standards Organizations,Such As ATEX,IECEx,and UL,Ensuring They Meet Stringent Safety Requirements For Use in Explosive Atmospheres.

By Integrating Explosion-Proof Motors Into Your Fog Cannon Systems,You Can Ensure a Higher Level of Safety and Reliability,Particularly in Environments With Explosive Hazards.

1.Used in Drilling Rigs,Refineries,and Pipelines Where Flammable Gases Are Prevalent.

2.Ideal For Environments With Volatile Chemicals and Fumes.

3.Essential For Underground Operations Where Explosive Dust and Gases are Common.

4.Used in The Production of Medications and Chemicals Where Safety and Cleanliness are Paramount.

5.Suitable For Environments With Combustible Dust,Such as Sugar or Grain Processing Facilities.

In Industries Where The Presence of Flammable Gases,Vapors,or Combustible Dust Poses Significant Risks,Ensuring The Highest Standards of Safety is Paramount.Explosion-Proof Motors Play a Pivotal Role in Mitigating These Risks By Providing Robust Protection Against Ignition Sources in Hazardous Environments.Engineered With Stringent Safety Measures and Durable Construction,These Motors are Designed to Operate Reliably in Conditions Where Explosive Atmospheres May Be Present,Such as Oil Refineries,Chemical Processing Plants,Mining Operations,and Pharmaceutical Facilities.

The Benefits of Employing Explosion-Proof Motors Extend Beyond Safety Alone.They Offer Unparalleled Reliability,Capable of Sustaining Continuous Operation Amidst Challenging Environmental Conditions,Thereby Minimizing Downtime and Optimizing Operational Efficiency.Moreover,Their Compliance With Rigorous Safety Standards and Regulations Ensures Adherence to Industry Norms,Facilitating Seamless Integration Into Diverse Industrial Applications Without Compromising on Safety or Performance.With a Reputation For Longevity and Cost-Effectiveness,Explosion-Proof Motors Represent a Prudent Investment For Industries Prioritizing Both Safety and Operational Excellence.Here are Some of its Advantages.

Safety:The Primary Benefit of Explosion-Proof Motors is The Enhanced Safety They Provide in Hazardous Environments,Protecting Both Personnel and Equipment.

Reliability: Designed to Withstand Harsh Conditions,Explosion-Proof Motors Offer Reliable Performance,Reducing The Risk of Operational Downtime.

Compliance:Using Explosion-Proof Motors Ensures Compliance With Safety Regulations, Which is Crucial For Industries Like Oil and Gas,Mining,Chemical Processing,and More.

Longevity:The Durable Construction of These Motors Leads to a Longer Lifespan,Providing a Cost-Effective Solution For Hazardous Environment Applications.

Dust Suppression Misting Cannons are Essential in Controlling Dust in Various Industrial Environments,Including Mining,Construction,and Demolition.These Specialized Systems Use Fine Water Droplets to Bind Dust Particles and Prevent Them From Becoming Airborne.When Dealing With Potentially Explosive Environments,Such as Coal Mines,It is Crucial to Use Explosion-Proof Motors to Avoid Accidental Ignition of Flammable Materials.

Key Features and Benefits:

High-Pressure Mist Cannons:High-Pressure Misting Systems Create Micro-Droplets That Encapsulate and Bind Dust Particles,Forcing Them to Fall.These Systems Can Cover Large Areas,Ensuring Comprehensive Dust Control.

Explosion-Proof Design:

Explosion-Proof Motors are Designed to Prevent Internal Sparks From Igniting Surrounding Flammable Gases or Dust,Making Them Ideal For Hazardous Environments.For Instance,Certain Models Like The "Explosion-Proof Fog Cannon High Pressure Misting System" Are Specifically Tailored For Such Applications.

Coverage and Flexibility:Misting Cannons Can Cover Distances Up to 100 Meters With Powerful Fans,Helping to Improve Visibility and Reduce Environmental Pollution.Adjustable Angles,Distances,Oscillation,and Spray Nozzles Provide Customizable Solutions to Meet Specific Site Requirements.

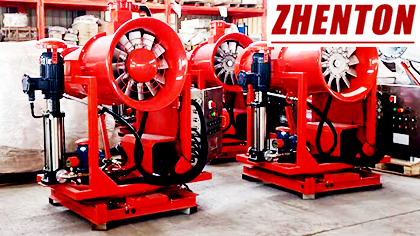

Durability and Performance:High-Quality Construction Ensures Long-Term Reliability and Efficiency.Models Like The ZhenTon Series are Known For Their Durability,With Systems Still Operational After Many Years.Heavy Dust Engine For Direct Installation on Machinery,Providing Targeted Dust Suppression.

When Selecting a Dust Suppression System,Consider The Specific Needs of Your Site and The Specifications of Available Models to Choose The Best Fit.

Here are The Key Parameters and Characteristics of Explosion-Proof Motors Typically Used in Fog Cannon Systems:

ATEX Standards: European Standards For Explosion Protection,Classified Into Different Explosion Protection Levels and Zone Classifications.

IECEx Certification:International Certification Standards Issued By The International Electrotechnical Commission,Also Including Various Explosion Protection Levels and Zone Classifications.

UL Certification:Certification Issued By Underwriters Laboratories For Explosion-Proof Motors, Applicable to The North American Market.

Design Features of Explosion-Proof Motors:

Explosion-Proof Enclosure:Typically Designed With a Special Enclosure That Can Suppress Flames and Thermal Energy in The Event of an Internal Explosion.

Sealed Design:Ensures That Electrical Components and Mechanical Parts Inside The Motor do Not Ignite Explosive Gases or Dust Outside.

Technical Specifications of The Motor:

Rated Power:The Continuous Operating Power of The Motor.

Rated Voltage and Frequency:The Designed Operating Voltage and Frequency of The Motor.

Protection Rating:IP Rating (Ingress Protection) Signifies The Motor's Ability to Resist Solid and Liquid Ingress,E.G.,IP65 Indicates Complete Dust Protection and Resistance to Jetting Water.→Dust Suppression Misting Cannons

Special Features and Accessories:

Temperature Detector:Monitors Internal Motor Temperature to Prevent Overheating.

Explosion-Proof Junction Box:Used For Safely Connecting Cables and Power,Preventing Arc and Spark Formation.

Materials and Durability:

Corrosion-Resistant Materials:Motor Components Typically Use Corrosion-Resistant Materials Such as Stainless Steel or Special Alloys to Withstand Long-Term Use in Harsh Environmental Conditions.

→Dust Control Sprayer Machine

These Parameters and Characteristics Help Users Select Explosion-Proof Motors Suitable For Their Specific Industrial Applications,Ensuring Safe and Reliable Operation of Equipment in Hazardous Environments.

ZhenTon Offers Multiple Models of Fog Cannons to Meet Various Customer Needs, Including Different Spray Distances,Processing Capacities,and Adaptability to Different Environments.The Fog Cannons Utilize Advanced Atomization Technology To Evenly And Finely Spray Water or Additives Into The air, Effectively Controlling Dust and Reducing air Pollutants.

ZhenTon Fog Cannons Prioritize Product Quality and Performance,Ensuring Stable Operation and Long Lifespan Suitable For Various Industrial and Environmental Applications.Some Models Feature Intelligent Control Systems That Support Remote Monitoring and Operation,Allowing Users to Adjust Atomization Effects and Operational Parameters in Real-Time.Ensure Minimal Impact on The Environment and Personnel During Operation.Are Widely Used in Construction Sites,Mines,Ports,Landfill Sites,and Atmospheric Management,Providing Effective Dust Control and air Purification Solutions.

ZhenTon,As a Manufacturer of Fog Cannons,Is Committed to Delivering High-Quality,Efficient Environmental Management Equipment.They Continually Innovate and Optimize Their Products to Meet Customer Needs in Environmental Protection and Health Safety. → Mining Dust Suppression